Radial Dovetail Box Construction

Some time ago I posted a blog about a dovetail joint I came up with. I call it the radial dovetail. It incorporates handcut dovetails, but rather than using the traditional 1:8 ratio for the dovetail angle for hardwood, each side of each tail varies and is drawn from a perspective point. Then the sides of the box were contoured to blend with the dovetail design.

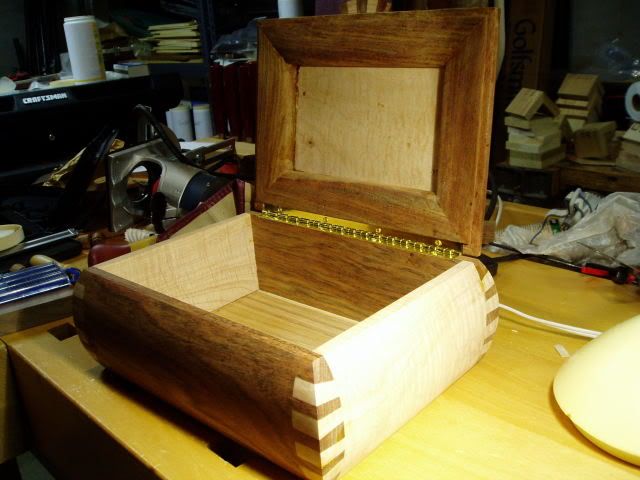

Here's a picture of the nearly completed box. It is made of curly maple, Carribean rosewood, and hickory.

I like to think of this box as a combination of radii and angles, and of corners and curves.

The general technique I use for dovetails can be seen in my blog on handcut double dovetails.

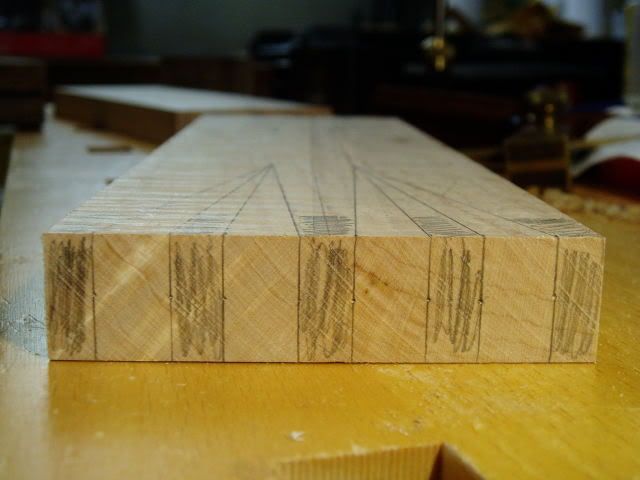

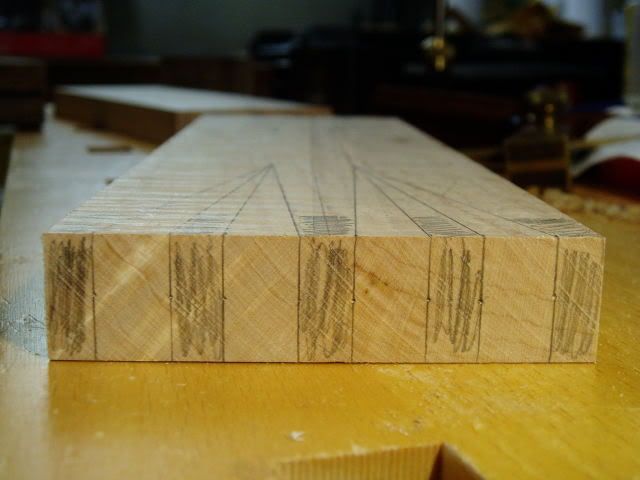

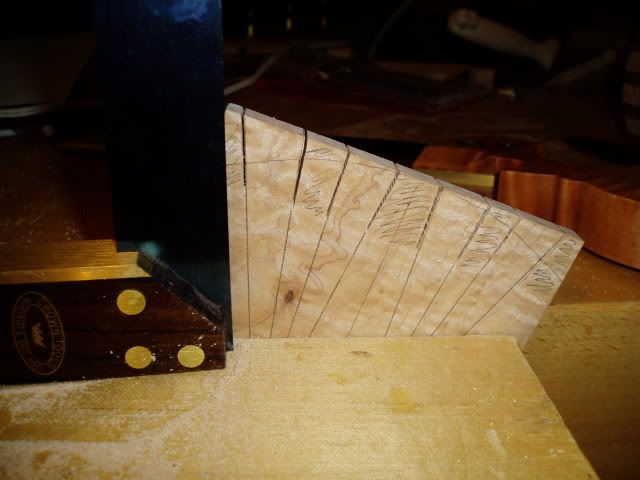

However, for each corner of this box, I used two perspective points to determine the dovetail angles. These are located 3 ½ inches from each corner and 3/8 inch from the mid-line of each (tail) side. The curly maple are the "tail sides". The pictures below shows these drawn up.

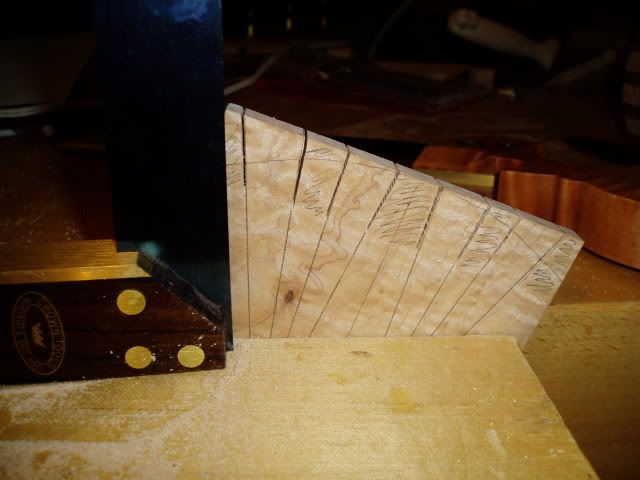

With this layout, note that the two pins adjacent to the middle pin are shaped like tails rather than pins. In other words the width of these pins at the corner or edge are wider (slightly) than they are toward the base of the pin. You can see this in the picture below showing the rosewood pins.

I think this helps the radial appearance of the box sides.

Then by using a large furniture makers router bit I rounded each side of the box to allow the contour to match the "radial" affect of the dovetails at the corners. This took several passes on the router table at varying heights and depths to achieve a smooth curved line to the sides that somewhat matched the perspective point used to draw the tails. It did take some hand sanding as well after these router table passes.

The lid is a frame/panel construction using a cross-grain spline to reinforce the corners. The frame was also contoured with various passes with different profiled router bits to achieve the complex curves both on the top of the lid and on the underneath side of the lid. Here are a few exploded views of the frame pieces and splines. The underneath contour is shaped in these pictures. The contour of the top of the lid was shaped after assembling.

Here's another picture showing the variety of contours used in the construction. In this picture the dovetails in the maple centerpiece of the lid have yet to be sanded flush.

The maple centerpiece in the lid was "inlaid" into the frame at a depth of 5/16 inch and incorporates the radial dovetail theme as well. The picture below again shows the radial dovetail layout lines for the centerpiece.

Below are a few pictures of the "inlaying" process for the lid's centerpiece which is made of curly maple. The perimeter edges of this centerpiece were rounded to blend into the contours of the box.

This is a mixture of Titebond III and Carribean rosewood sawdust used to glue in the centerpiece.

The lid handle also carries the radial dovetail theme and is joined using an 1/8 thick by 1 ½ inch wide mortise/tenon joint.

The base of lid handle had to be formed to match the contour of the lid frame.

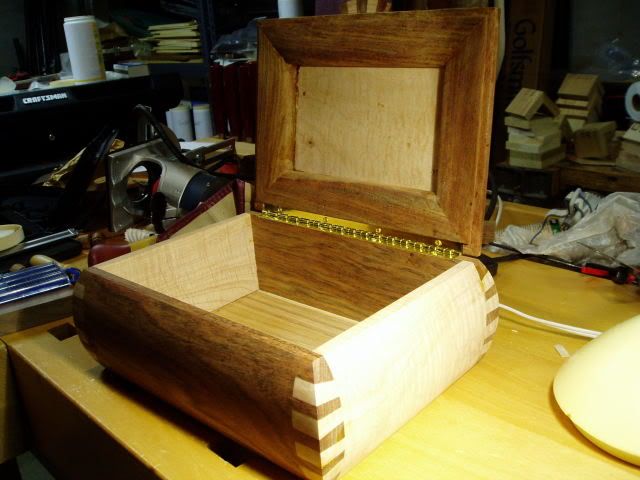

Here's a picture of the open box nearly complete.

The feet were hand turned and have a ¾ inch wide by 1/8 inch deep tenon that is mortised into the hickory base. Below are a few pictures:

As soon as I get this completed I'll post as a project.

I hope you enjoy the blog.

Some time ago I posted a blog about a dovetail joint I came up with. I call it the radial dovetail. It incorporates handcut dovetails, but rather than using the traditional 1:8 ratio for the dovetail angle for hardwood, each side of each tail varies and is drawn from a perspective point. Then the sides of the box were contoured to blend with the dovetail design.

Here's a picture of the nearly completed box. It is made of curly maple, Carribean rosewood, and hickory.

I like to think of this box as a combination of radii and angles, and of corners and curves.

The general technique I use for dovetails can be seen in my blog on handcut double dovetails.

However, for each corner of this box, I used two perspective points to determine the dovetail angles. These are located 3 ½ inches from each corner and 3/8 inch from the mid-line of each (tail) side. The curly maple are the "tail sides". The pictures below shows these drawn up.

With this layout, note that the two pins adjacent to the middle pin are shaped like tails rather than pins. In other words the width of these pins at the corner or edge are wider (slightly) than they are toward the base of the pin. You can see this in the picture below showing the rosewood pins.

I think this helps the radial appearance of the box sides.

Then by using a large furniture makers router bit I rounded each side of the box to allow the contour to match the "radial" affect of the dovetails at the corners. This took several passes on the router table at varying heights and depths to achieve a smooth curved line to the sides that somewhat matched the perspective point used to draw the tails. It did take some hand sanding as well after these router table passes.

The lid is a frame/panel construction using a cross-grain spline to reinforce the corners. The frame was also contoured with various passes with different profiled router bits to achieve the complex curves both on the top of the lid and on the underneath side of the lid. Here are a few exploded views of the frame pieces and splines. The underneath contour is shaped in these pictures. The contour of the top of the lid was shaped after assembling.

Here's another picture showing the variety of contours used in the construction. In this picture the dovetails in the maple centerpiece of the lid have yet to be sanded flush.

The maple centerpiece in the lid was "inlaid" into the frame at a depth of 5/16 inch and incorporates the radial dovetail theme as well. The picture below again shows the radial dovetail layout lines for the centerpiece.

Below are a few pictures of the "inlaying" process for the lid's centerpiece which is made of curly maple. The perimeter edges of this centerpiece were rounded to blend into the contours of the box.

This is a mixture of Titebond III and Carribean rosewood sawdust used to glue in the centerpiece.

The lid handle also carries the radial dovetail theme and is joined using an 1/8 thick by 1 ½ inch wide mortise/tenon joint.

The base of lid handle had to be formed to match the contour of the lid frame.

Here's a picture of the open box nearly complete.

The feet were hand turned and have a ¾ inch wide by 1/8 inch deep tenon that is mortised into the hickory base. Below are a few pictures:

As soon as I get this completed I'll post as a project.

I hope you enjoy the blog.