The Beginnings, where I come from, and where I'm going.

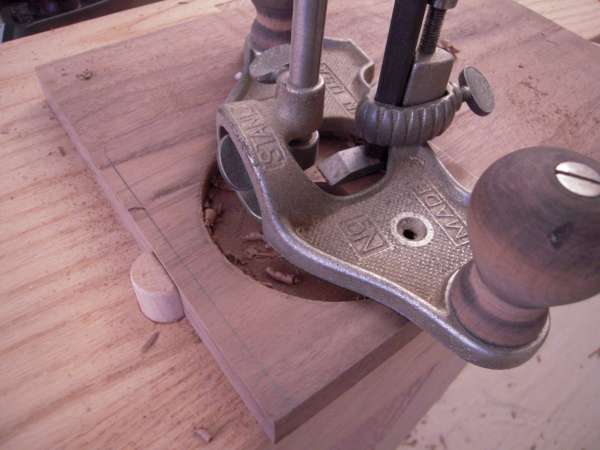

A Workbench… I figured it was about time I make one. I've been working with hand tools primarily for almost a year now, and my "workbenches" has had many forms. My primary work horse was the work mate. Now, this works, but is far from ideal.

![Image]()

![Image]()

![Image]()

And so it goes on. I've also used a few other arrangements as well.

Parallel jaw clamps, clamped to a folding table, clamped to a porch support beam. This actually worked surprisingly well, until there was any sort of side pressure… then the end would start to dance around

![Image]()

![Image]()

![Image]()

I've also used a sitting bench with a single clamp as a planning stop.

![Image]()

![Image]()

Ok, I think you've got the point. I've made do for some time now, in various different ways. I feel it's now time to get a real bench to work on. Thus begins the journey.

Here's the basic design. I will also add a leg vise, and an end vise

![Image]()

That is all I've got for this one. I will have an update for some more progress in the coming days.

Thanks for checking it out!

A Workbench… I figured it was about time I make one. I've been working with hand tools primarily for almost a year now, and my "workbenches" has had many forms. My primary work horse was the work mate. Now, this works, but is far from ideal.

And so it goes on. I've also used a few other arrangements as well.

Parallel jaw clamps, clamped to a folding table, clamped to a porch support beam. This actually worked surprisingly well, until there was any sort of side pressure… then the end would start to dance around

I've also used a sitting bench with a single clamp as a planning stop.

Ok, I think you've got the point. I've made do for some time now, in various different ways. I feel it's now time to get a real bench to work on. Thus begins the journey.

Here's the basic design. I will also add a leg vise, and an end vise

That is all I've got for this one. I will have an update for some more progress in the coming days.

Thanks for checking it out!